The packaging industry is in constant flux. Fueled by e-commerce growth, rising consumer demand for sustainable packaging, and increasing product variety, the need for efficient, reliable, and adaptable packaging equipment has never been greater. Manufacturers are under immense pressure to optimize their processes, reduce waste, and minimize downtime. At the heart of many packaging machines lies a critical component: the gear motor. Selecting the right gear motor isn't just about choosing a motor; it's about strategically investing in overall system performance, energy efficiency, and long-term cost savings. This article delves into the key considerations surrounding gear motor selection for packaging equipment, examining the factors that contribute to efficiency and highlighting how innovative solutions can address the challenges of today's dynamic market. The recent surge in automation driven by AI and robotics is further amplifying the importance of robust and precise motor control, making gear motor selection even more crucial.

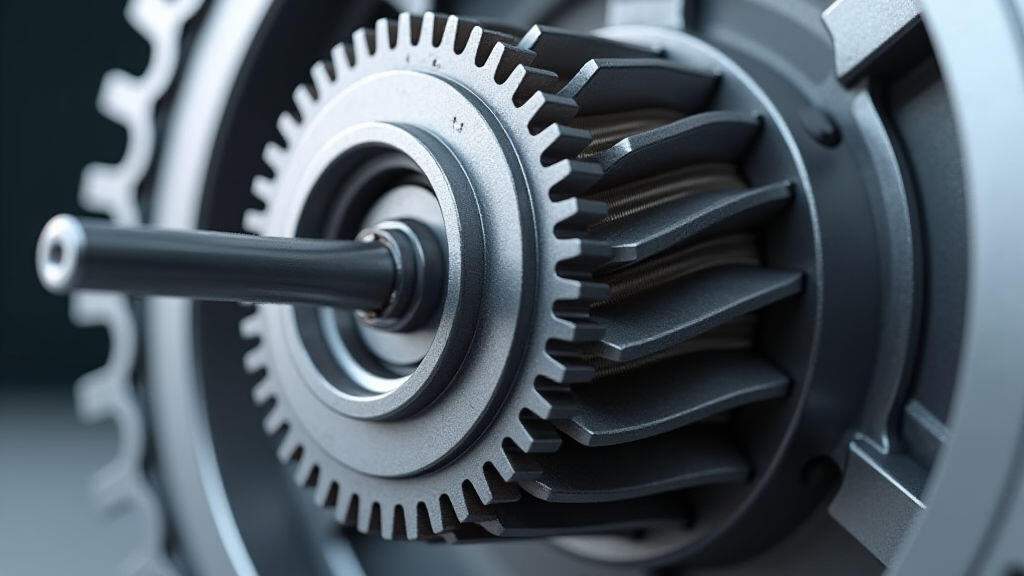

Gear motors are electromechanical devices that combine the power of an electric motor with the speed reduction and torque amplification capabilities of a gear reducer. In packaging equipment, they perform a vast range of tasks, including:

The efficiency of these processes directly impacts throughput, product quality, and overall profitability. A poorly selected gear motor can lead to reduced speed, inconsistent motion, increased energy consumption, and premature equipment failure – all detrimental to a packaging line's performance.

Choosing the right gear motor involves considering several crucial factors:

1. Torque Requirements: This is arguably the most important factor. The gear motor must be able to deliver the required torque to overcome the loads imposed by the packaging machine’s components. A detailed load analysis is essential to determine the peak and continuous torque demands. Over-sizing the motor results in wasted energy and increased costs, while under-sizing leads to performance issues and potential damage. Accurate calculations should include static torque (for holding loads) and dynamic torque (for accelerating and decelerating loads).

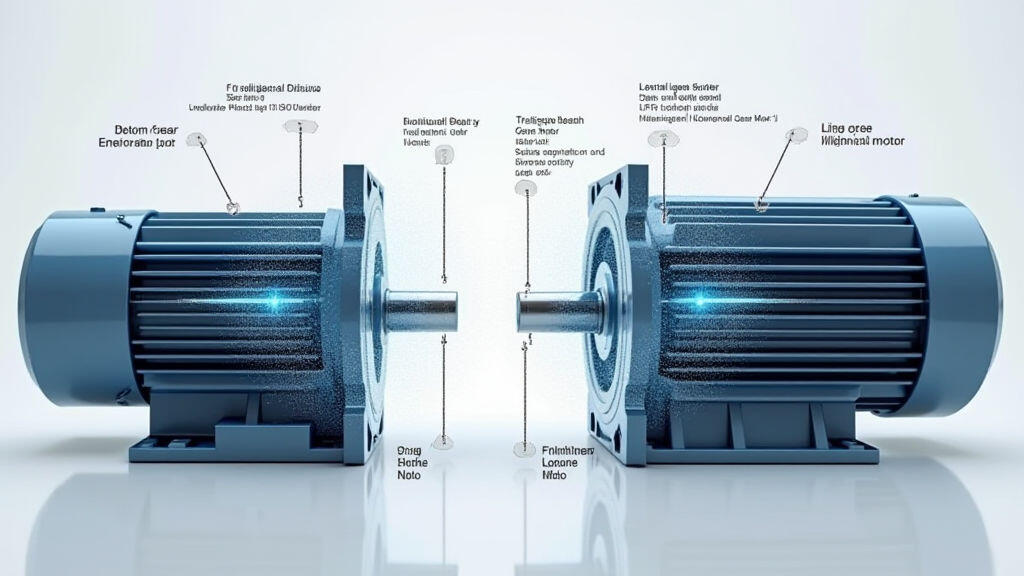

2. Speed and Gear Ratio: The required speed is dictated by the specific task. Gear ratios are used to reduce the motor’s speed and increase its torque. The optimal gear ratio depends on the machine's speed and torque requirements. Higher gear ratios provide greater torque but reduce speed, while lower gear ratios offer higher speed but lower torque.

3. Efficiency: Energy consumption is a major concern for packaging manufacturers. Gear motors with higher efficiency minimize energy waste and reduce operating costs. Efficiency ratings are typically expressed as a percentage, indicating the ratio of mechanical power output to electrical power input. Modern gear motors often utilize optimized gear designs, high-quality materials, and advanced lubrication systems to maximize efficiency.

4. Size and Weight: Physical constraints within the packaging machine often limit the available space for the gear motor. Therefore, size and weight are important considerations, particularly in compact packaging solutions.

5. Reliability and Durability: Packaging equipment operates continuously and under demanding conditions. The gear motor must be reliable and durable to withstand prolonged use and minimize downtime. Factors contributing to reliability include high-quality materials, robust construction, and effective lubrication.

6. Environmental Considerations: With growing emphasis on sustainability, energy-efficient gear motors are becoming increasingly desirable. Additionally, the use of environmentally friendly lubricants and materials aligns with responsible manufacturing practices.

Several types of gear motors are available, each with its own advantages and disadvantages. The most common types include:

The trend towards Industry 4.0 and the increasing use of AI in packaging are driving the development of intelligent gear motors. These motors incorporate sensors, microcontrollers, and communication interfaces that enable real-time monitoring, control, and diagnostics. MES-Drive, for instance, offers gear motors with integrated sensors for monitoring temperature, vibration, and motor current, allowing predictive maintenance and preventing unexpected downtime. These features are crucial for optimizing packaging line performance and ensuring consistent product quality.

The future of gear motor selection for packaging equipment will be shaped by several key trends:

In conclusion, selecting the right gear motor is fundamental to achieving optimal efficiency in packaging equipment. It's more than just a component selection; it's a strategic investment that influences throughput, product quality, energy consumption, and long-term cost savings. As the packaging industry embraces automation and strives for greater sustainability, the demand for intelligent, energy-efficient, and reliable gear motors will continue to grow. Companies like MES-Drive are at the forefront of this evolution, offering innovative solutions that meet the evolving needs of the packaging market and underpin the advancements in AI-driven automation. The future of packaging efficiency is intrinsically linked to the sophisticated engineering within these critical components.

Leave A Reply

Your email address will not be published. Required fiels are marked